The company was founded in 2014, firmly backed with 15 years of experience in the printing and typographic industries. We are here to support specialist bookbinding practices for printing houses, publishing houses, advertising agencies and marketing busisnesses.

To answer the market demand, we successively built and developed a range of major services types, to incude:

– Paper Gluing/Laminating;

– Hot-stamping;

– Heat-shrink and polyethylene film wrapping;

– Hard cover

– Zip-wire binding.

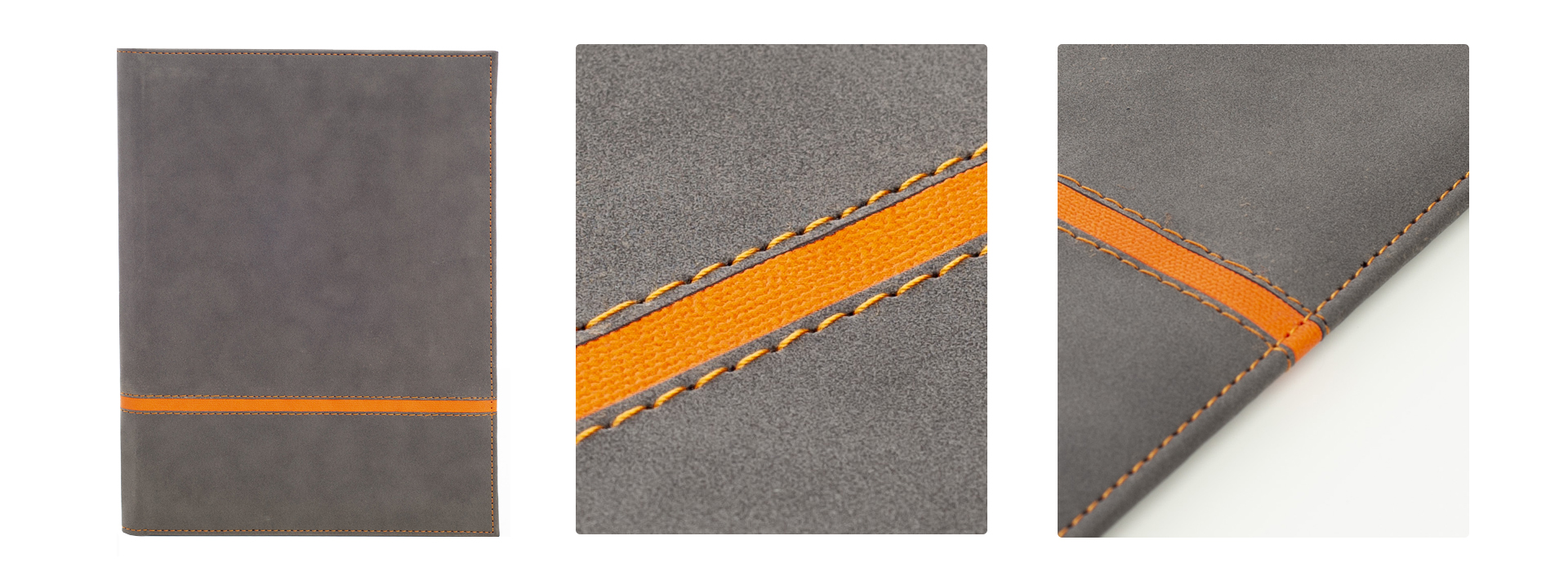

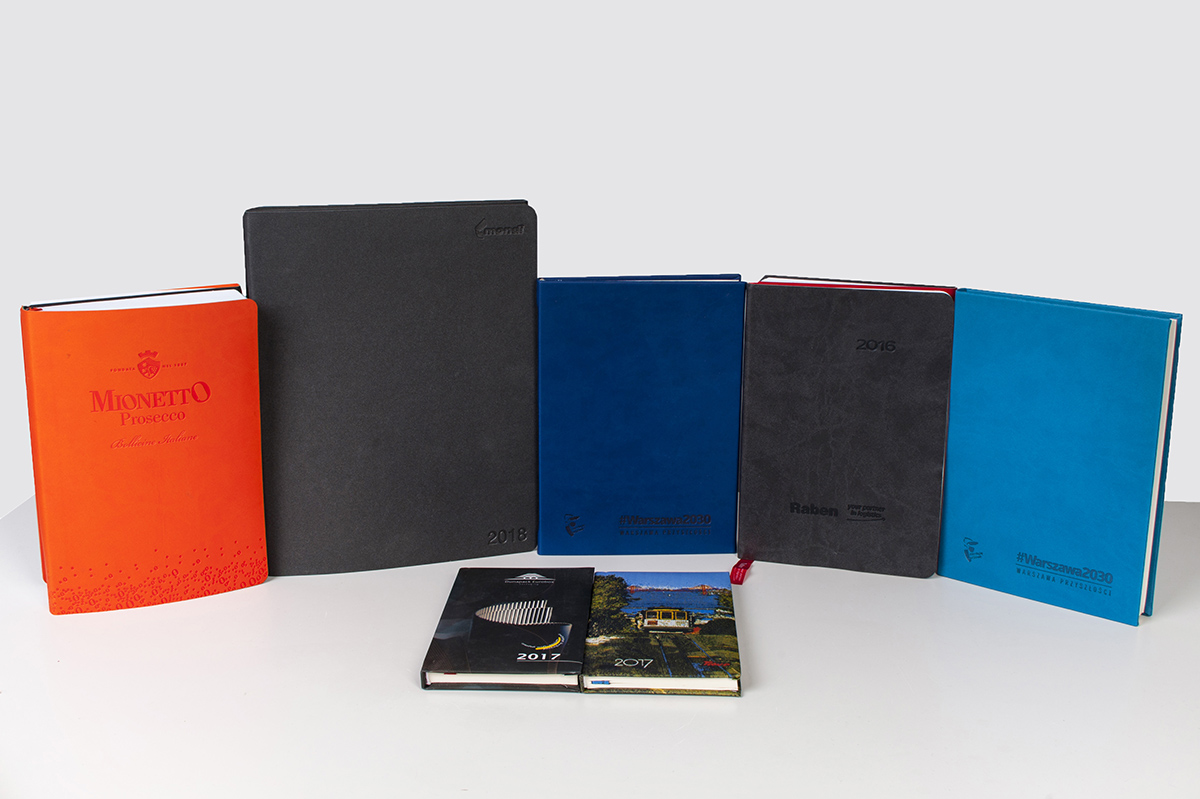

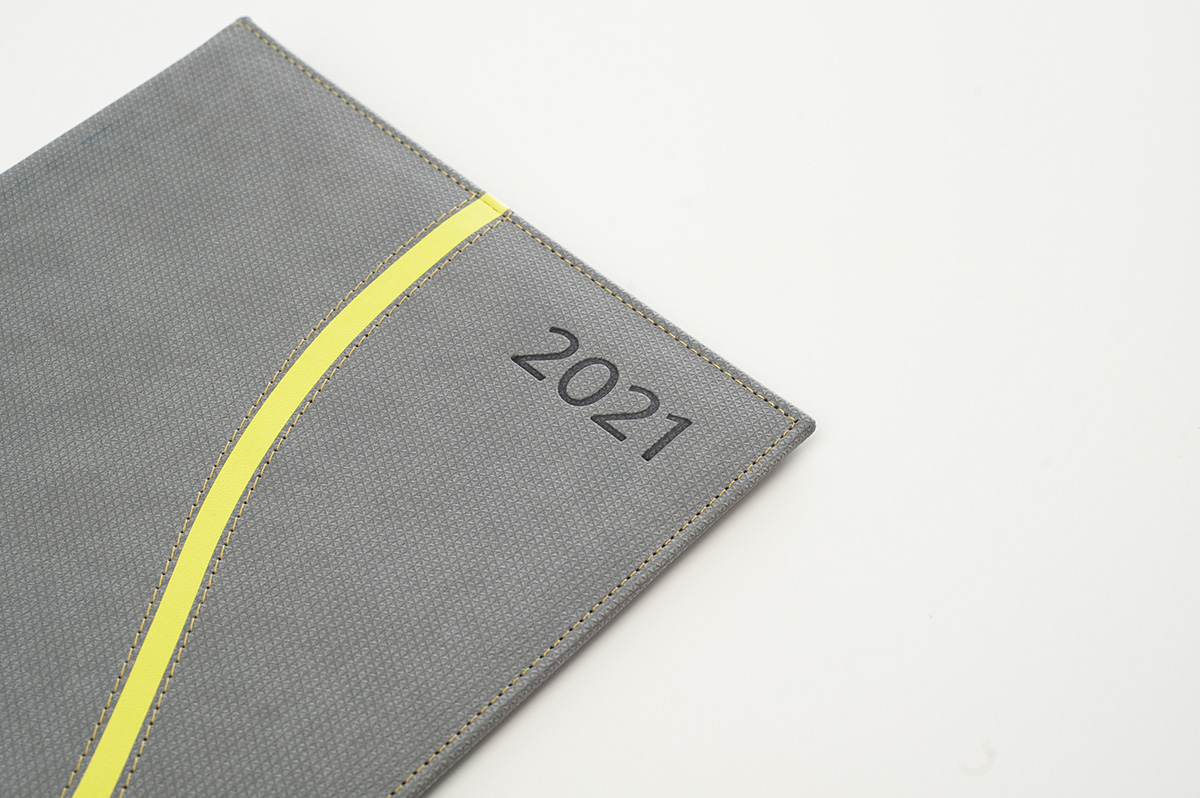

Since day one, we have been dedicated to developing production techniques for personalised hemmed (cloth-case) covers for calendars, notebooks and similar products.

This work is our passion and we are always looking for new inovative solutions to be able to deliver almost any typograhic product, from any material and to an excellent standard. We value quality, take pride in originality and ingenuity and welcome any project, no matter how challenging!

Who we support?

We provide a wide range of typographic and post-press services that will benefit:

- Printing houses;

- Post-press companies

- Adertising agencies

- Calendar and stationery manufacturers;

- Publishing houses;

- Any many others.

Go to ‘Our Offer’ to learn about the full range of services.

What makes us stand out?

We try to be perceived as a good partner in cooperation, especially when the implementation time plays a crucial role.

The quality of services is our recipe for long-term relationships with customers.

The location of the company in the northern part of Łódź, near the Warsaw-Gdańsk junction, favors easy logistics.

We focus on flexibility and comprehensiveness as well as an optimal offer based on many years of experience in the industry.

Unusual and sometimes troublesome projects are a field for us to show off.

Simply put, WE RESPECT YOUR TIME. CHECK US OUT

Gluing/Lamination

Laminating process technique/process of manufacturing a material in multiple layers.

We’re able to work with almost any material:

– Offset paper, chalk paper, plain, all-thickness solid and corrugated cardboard, PCV or PE plastics, foam and other ‘challenging’ materials.

– Cold roll lamination (using dispersion glue) or hot roll lamination (using animal glue).

– One or two-sided lamination (e.g. chalk paper – cardboard – chalk paper).

– Maximum dimensions 1000 x 700 mm (B1 format).

We pride ourselves in outstanding attention to detail and the polished, quaity look and feel of the finished product.

Supplemntary services include:

– semi-automatic assembly of calendars and multi and single-partite calendar headers.

– semi-automatic application of two-sided foil.

– hand-assembly with hot-melt glue.

We produce a variety of types of covers, templates, binders, clip-board etc. As well as laminated packaging for premium products.

– multi-element and assymetric covers;

– Wide spectrum of products: printed paper-backs, ornamental patterned papers, PE and PCV wrapsand natural leather.

– multiple combinations of two or more types of lamination including print-on wrapping – all finished to your indovidual specification.

– Rounded corners option.

– Edge hemming and any other type of hemming within the surface of any over.

– Hot-stamping or laser personalisation.

– Finochrom style chrome embossing (logo, date etc).

– maximum dimensions – 1000 x 470 mm;

The covers can be fisnished with an inbedded block design whilst binders/dividers or templates can be finished with any element or design of your choice.

Hot stamping is a form of product finishing that adds decoretaive elements using thermoprint foil.

– Pigmented, metallic and hologram foils.

– Precise, detailed finish even for small or highly intricate designs.

– Surface embossing, 3D or raised effect.

– Printing and embossing on paper, cardboard, foil, typographic wrapping.

– minimum volume from as little as 100 items.

– Maximum dimension – 300 x 200 mm.

Ou semi-automatic heat-shrink foil wrapping machine ensures a highly aesthetic and protective prodcut finish no matter what type (typugraphic or industrial) materials are used in the process.

Our fleet also holds a device which enables highly efficient automated packaging of single-unit prodcucts such as newspapers, folders, books, inserts or newsletters. It’s also ideal for mass-mail distribution.

– polyethylene film wrapping – 25-50 microns.

– medium to high production volumes.

– maximum thickness suitable for wrapping – 20 mm.

– Maximum dimensions – 500 x 400 x 250 mm.